Advancing sustainable materials development

Researchers from SoftComp partner KU Leuven, Belgium, have introduced a novel strategy to upcycle humins, a major by-product of biorefineries, into new materials , advancing materials development using sustainable building blocks. Humins, black, tar-like substances formed during the acid-catalysed treatment of biomass that can account for up to 50% of total carbon loss, have long posed a challenge to commercialisation efforts due to their variable composition and difficult handling properties.

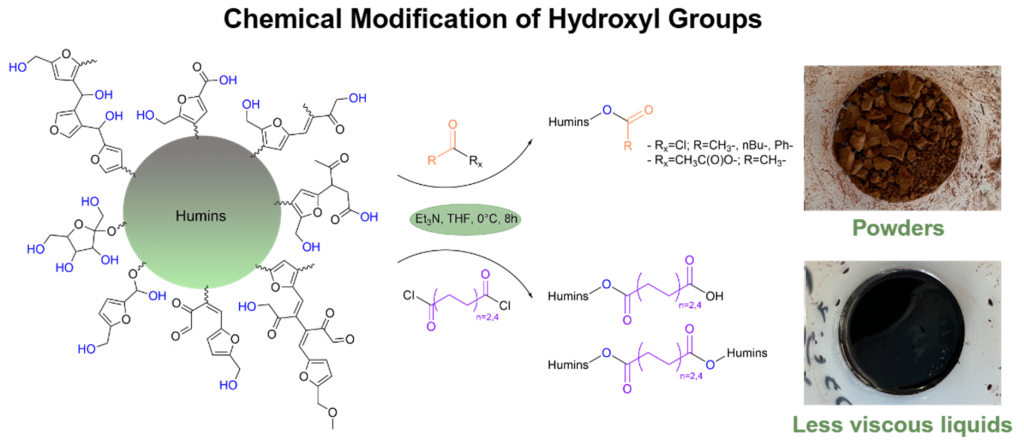

However, the SoftComp researchers have now developed a method to transform humins into fine powders or low-viscosity liquids through esterification reactions with targeted reagents. This approach tackles the solubility and thermal stability challenges of humins by modifying their molecular structure and achieving uniform physical states.

Building on this success, the team has also developed a one-step synthesis method to incorporate humins into polyester matrices, yielding high-strength thermoplastic elastomers. Blending humins with polylactic acid (PLA) – a biodegradable polymer derived from bio-based sources – at a 1:1 weight ratio resulted in the formation of foam-like structures with improved mechanical properties, phase stability, and uniform morphology. The study was supported by comprehensive characterisation using various analytical techniques.

Overall, this work highlights the potential of humins as versatile building blocks for producing added-value materials, advancing sustainable materials development, and expanding the applications of renewable resources. Successful valorisation of these biorefinery side-streams has the potential to significantly reduce global reliance on fossil fuels and mitigate environmental impact, aligning with sustainable development goals.

Read more:

Kandemir D. et. al, Chem. Sus. Chem. (2024), e202400403

SoftComp partner:

KU Leuven